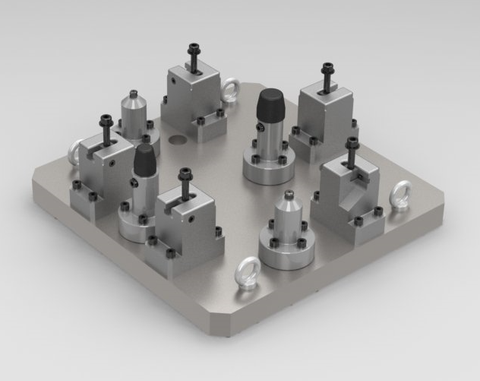

Machining Fixture for a Marine Outboard Engine Casting

The Brief:

Design a work holding fixture to accurately locate a large aluminium casting for a marine outboard engine during final machining on 5-axis milling machine.

The Solution:

Fixture with zero point mounting to the machine pallet.

Precision part location by 2-pin locators

Integral loading guides to aid part loading

Simple hold down bolt arrangement with replaceable inserts.

Highlights:

Designed from Concept to Manufacture Ready Drawings

Design Leadtime 1 Week

Fixture Technical Data supplied to clients in house software format

Lifting Fixture and Manipulator for a Large Industrial Gas Turbine NGV

The Brief:

Design a handling attachment and base unit to enable the safe lifting, transport and inspection of a large industrial gas turbine nozzle guide vane weighing over 100kg.

The Solution:

Bespoke lifting attachment for use with over head crane featuring mechanical turn over mechanism and a wheeled base unit for safe transport around a factory environment.

Highlights:

Design included comprehensive Technical File including: Stress Analysis and Operator Manual in accordance with Machinery Directive Requirements for CE Marking.

Design Leadtime 4 Weeks

DFMEA and Significant Hazards Assessment included in Winmore Engineering Design Verification & Sign-off Process.

Full product data supplied to the clients in house software format.

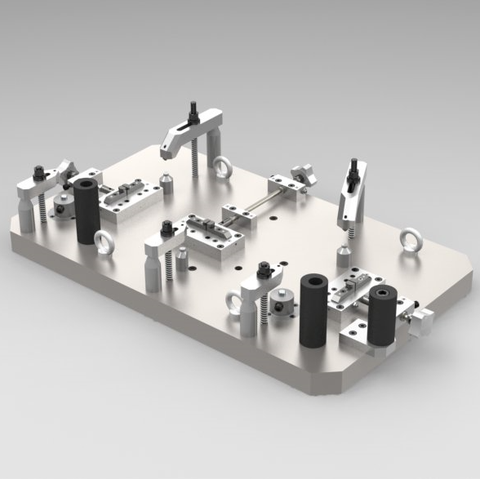

Machining Fixture for Large Industrial Diesel Engine Cylinder Head Casting

The Brief:

Design a work holding fixture to accurately locate a large cast iron cylinder head casting for an industrial 6-cylinder diesel engine.

The Solution:

Work holding fixture featuring innovative expanding locators to accurately position cast component.

Adjustable touch-lock supports and zero-point fixture mounting. Integrated loading guides enable simple loading in production environment.

Highlights:

Designed from Concept to Ready for Manufacture Drawings

Full product technical data supplied to the clients in house software format.

Design Leadtime 3 Weeks